Industrial Robot Orchestration

iOS app development for Siemens during iPraktikum at TUM

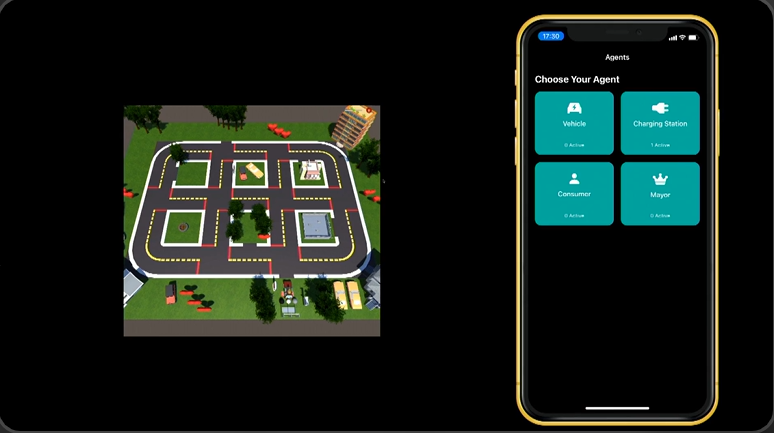

Industrial Robot Orchestration System

As part of the iPraktikum applied course at the Technical University of Munich, I collaborated with a team of student developers on an industry partnership project with Siemens.

Project Overview

Our team was tasked with creating an orchestration system for industrial robots, addressing the complex challenge of managing both autonomous and non-autonomous agents within the same industrial environment.

My Contribution

Within this project, I took primary responsibility for developing the auctioning algorithm - a critical component of the system that optimally matches tasks and requests between different agents in the industrial environment. This algorithm needed to:

- Efficiently distribute workloads across available robots

- Prioritize time-sensitive tasks

- Handle conflicts between autonomous and manual operations

- Adapt to changing conditions on the factory floor

The implementation required careful consideration of both technical constraints and real-world industrial workflows, ensuring the system would be practical in actual manufacturing environments.

Development Process

Working in close collaboration with industry professionals from Siemens, our team followed professional software development methodologies including:

- Agile development with regular sprint reviews

- Comprehensive testing and quality assurance

- Client-centered design thinking

- Documentation and knowledge transfer

The practical experience gained through this industry collaboration provided valuable insights into developing enterprise-grade applications that meet rigorous industry standards.

For more information about this project, including detailed design reviews and client acceptance tests, visit the applied software engineering group website.